engineered timber wood composite waterproof laminate flooring

Product Description

engineered timber wood composite waterproof Laminate Flooring

Main features:

(1) Environmentally friendly, recyclable.

(2) Elegant nature wood grain texture and touch, with wood scent

(3) Favorable mechanical performance, stable over a wide temperature range.

(4) Cost low in maintenance, economic.

(5) UV resistance, Fade resistant Durable

(6) Easily and conveniently installed and cleaned.

(7)Long service life, it can preserve about 20~30 years under normal use.

(8) Weater resistance ,100% recyclable ,Suitable From -40 to 60 degress centigrade

(9) different colours for your choices

engineered timber wood composite waterproof laminate flooring

1. Environmental friendly, non-pollution, no toxic chemicals.

2. Waterproof, mildew resistant, corrosion resistant.

3. WPC have good workability and can be shaped using conventional woodworking tools.

4. Recyclable.

5. Good appearance, Look like natural wood.

6. Colorful, less maintenance.

The contrast of WPC and Real Wood:

engineered timber wood composite waterproof laminate flooring

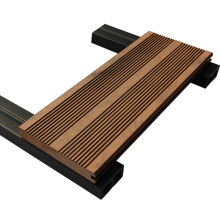

WPC Decking installation is very easy !

We could supply the installation Accessories as below.

You can refer the installation instruction as following and also can refer the installation video on our company website:

Detailed installation instruction:

1. Before installing the joist, make sure the ground is flat and solid so that the joist can be fastened tightly on the ground. Then dig holes with percussion drill in the deck area and bury the plastic tube into the holes.

2. Take the buried expansion tube as center, put the joist stably on the center line, pierce the joist with pistol drill and nail the screw into the expansion tube

3. Nail the expansion screw into the top of the vertical joint of two joists.

4. Put flat the deck along the vertical direction of joists, the ending deck can be fixed on the joist with screw to make sure the accuracy of it being the base floor for other decks.

5. Install clips on the other side of the first deck, and start installing decks in order.

6. Install 2 joists in the longitudinal joint of two decks

7. To avoid possible deformation caused by temperature change, joists can not be tied too closely.

8. Outside the last deck, use the same installation method as that of the first deck, install edge seal and terminal sealing board.

engineered timber wood composite waterproof laminate flooring

COOWIN owns two big manufacturing and processing plants at Qingdao, we have strong technologies and capabilities of production. “COOWIN” brand has been accepted by the world. It strictly follows up United States ASTM certification standards, CE certification standards and got Chinese CNAS. “COOWIN WPC” products have been exported to North America (United States, Canada), South America (Bolivia), Europe (England, Norway, Portland and Iceland), Asia (Korea, Singapore, India, Saudi Arabia, and Dubai) and Australia, etc. There are over 50 countries and regions using our “COOWIN WPC” products.

engineered timber wood composite waterproof laminate flooring

carton comer to protect the edge of the product. For the loading and unloading goods, don't worry about it,we designed one special pallet for this wpc product.

Packing materials: plastic film, cardboard, plywood(for LCL good only), tarpaulins, strappings

Shipping: seaworthy pallet

Port: Qingdao port.(Other port of China is also okay for us)

Installation Instructions Of WPC Hollow Decking

Groover surface Project

Sanding/Embossing Surface project

16 Years Experience about decking project

COOWIN Group was built in the year of 2000. During the 16 years development, we had exported to about 50 countries and regions. The most important thing is that there are nearly all good feedback from the market due to the high quality and best design.

The following pictures are shows the small groove surface projects for you specially.

engineered timber wood composite waterproof laminate flooring

1- How to install WPC outdoor floor?

Generally, it should install keel first. Fix the WPC board on the keel using nail gun,

and then plug another WPC board. One after another till the installation is finished.

2- How long is the service lifetime of WPC floor?

It is about 25-30years under ideal situations.

3- Do WPC products need painting?

As the difference with the wood, WPC products themselves own color, they need not extra painting.

4- What color can you provide?

Generally, we provide 8 main colors as Cedar, yellow, red pine, red wood, brown, coffee, light grey, blue grey.

And also, we can make special color per your request.

5- How to make the defective Restoration?

We recommend sanding the finish of the surface. After sanding ,

some of the plank will get back to the original appearance.

6- How to due with the Rust Stains, Ground-In Dirt and Grime?

You can use a cleaning product containing oxalic or phosphoric acid base to lighten or remove the rust or dirt.

7- How many tons can you loaded in one 20ft container ?

We can loaded about 20 tons in one 20ft container for hollow decking, And 26tons for one 40ft container. For the solid board, we can load about 23Tons in one 20ft container. And 26ton in one 40ft container.

8- Where is your factory?

Our factory is located in Qingdao city, the north of China, a beautiful seaside city. Welcome to visit our factory when you are free.

9-Where will use WPC products?

WPC products are widely used currently.

For outdoor, it was mainly used at gardens landscape, the beach road, villa yard, etc;

For indoor, it was mainly used for kitchen, balcony, TV setting wall, etc.

10- The raw material of COOWIN WPC Composite decking

50% wood flour, 38% plastic (HDPE), 12% additive. It is co-extruded with a polyethylene top layer for ultra low-maintenance performance. We can also adjust the formula of raw material according to your request.

12 - Other model of WPC decking

Any interest, contact me for more details !

Product Categories : Solid Composite Decking

Premium Related Products